Common Factors affecting the premature loss of polish on stone

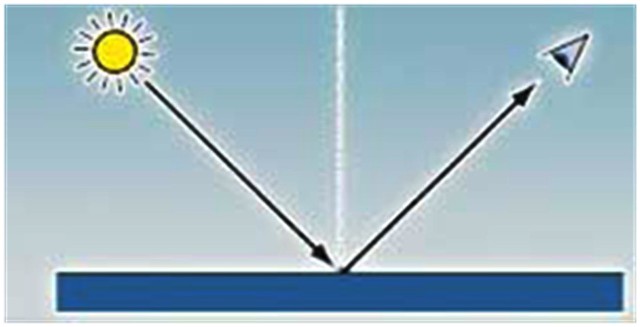

There are a number of common factors that can create a perception of premature loss of gloss on natural stone. But firstly let’s have a look at why stone actually “shines”. Shine or gloss effects are due to an interaction between light and the physical properties of the surface. If a source of light (incident) is reflected on to a surface the angle of light reflected back is equal to that of the angle of the source of light.

Perhaps more importantly when light hits a smooth surface the reflected light is not diffused so we receive it in a more pure form, which we interpret as reflection.

An obvious example is the sea on a windy day (it is rough hence the reflected light is scattered) where we see no reflection as opposed to a calm day (the water is smooth reflecting light directly) where high reflectivity is more obvious.

Angle of incidence (source of light) is equal to the angle of reflection

When it comes to stone, reflection is not only affected by the texture of the surface but also the type of mineral and crystal structure. For example granite has a much higher quantity of silica or quartz than say limestone. This means firstly that the surface can be mechanically or chemically engineered to be smoother than limestone that is rich in calcium carbonate. But also the crystal structure in the granite reflects light in a more direct fashion than the calcium carbonate so not only do we see a higher polish and shine on the granite but also more colour intensity and clarity.

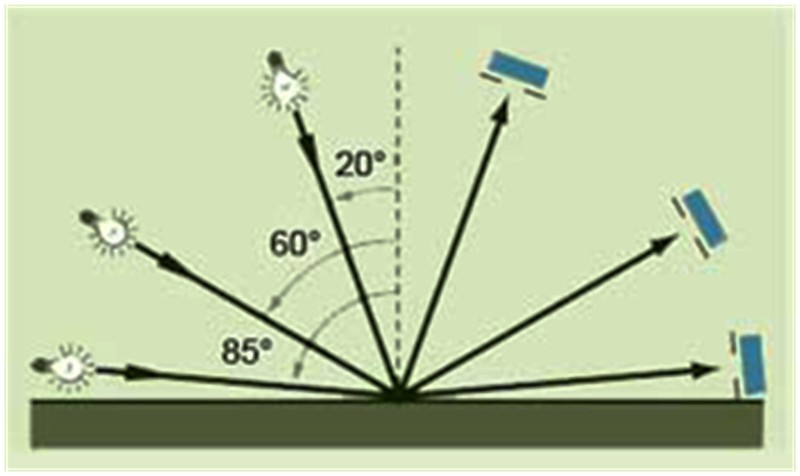

The gloss or polish of a surface can be measured. This is done using a commercially available Gloss Meter. These work by directing a source of light on to a surface at a specific angle and measuring the amount of light reflected back. The amount of reflection is quantified as units of gloss or GU. For stone and ceramics the most common range of angle for the source of light used for measurement is between 45 and 60 degrees.

Angle of incidence changes depending on the type of surface being measured.

There are standards to regulate gloss measurement such as ASTM D523 (similar to ISO 2813) that is relevant to high gloss surfaces and materials such as stone.

There are even more specific ones for ceramics such as ASTM C346 and C584.

Gloss meters can be very useful especially in determining things such as consistency of polish, (for example within a batch or between batches of tile or stone) the quality of a restorative process or if a polished surface has been damaged or impaired in anyway.

In many cases it is very easy to see when the polish of a stone is damaged such as when the polish is scratched or chemically etched.

However there are instances where the overall degree of polish is noticeably and seemingly reduced without an obvious reason or source.

It these instances I wish to address, as they are in fact the most common.

The following constitute the most frequent reasons I have encountered for a premature loss of polish on natural stone. Note that it is not always a single factor at work; in many cases it is a combination of the following factors that create the problem.

Grout Haze: As most stone is grouted using the smear method complete removal of grout residue is imperative to leaving the full reflectivity of the stone in tact. As most stone use a narrow grout joint there is an ever‐increasing use of high polymer modified grouts.

These insure the high compressive and bond strengths required to maintain the grout in such narrow joints.

However these same characteristics make the removal of grout residue more difficult.

If not completely removed the overall degree and impression of the polish will be greatly reduced due to an increase in scattered light.

Poor Application of a Sealer: A high percentage of polished stone is sealed using impregnating or penetrating sealers. Although designed to sit below the surface of the stone it is reasonably common for some sealer residue to sit on the surface.

This is due in the most part to poor application where either too much sealer is applied and or the residue sealer is not removed completely after application. Any sealer left on the surface will distort the reflected light resulting in a reduction in the overall perceived polish.

Note that as sealers are created using a variety of different compounds and components some sealer residues will have more impact on the reduction in polish than others.

Efflorescence: Most of us are familiar with Efflorescence (soluble salts) as easily visible white deposits on the surface of stone, tile, cement or masonry.

However in many cases the first stage of efflorescence is a very fine tight crystal that is not white. It is this first early stage, when the efflorescence is first forming on the stone surface that observations are often made of a poor degree of polish.

Removal of the efflorescence will in most cases restore the polish.

However if the soluble salt is not removed reasonably quickly it can (through expansion and contraction) damage the surface and the polish.

Poor Maintenance: This is perhaps the most obvious cause.

If a floor is not clean dirt can scatter light creating a loss of gloss.

However improper use of cleaning chemicals during maintenance can also affect the polish.

When using a daily cleaner these should be used as directed and not mixed too strongly. For example a safe cleaner such as Aqua Mix Concentrated Stone and Tile Cleaner (Recommended to be diluted at a ratio of 1:126 cleaner/water for polished stone) will leave a residue on the surface when mixed and applied too strong adversely affecting the perception of shine.

Some alkaline cleaners commonly used for heavy‐duty maintenance can also leave a residue (quite often an off‐white residue) on the stone surface if not properly rinsed.

Surface traffic: The very first stage of surface abrasion created by surface traffic commonly manifests itself as a slight loss of gloss.

It is of course a detailed network of very fine scratches that, as they get larger and deeper, eventually become evident as surface wear.

There are many more reasons why the polish on natural stone can be prematurely reduced or compromised. However in my experience the above factors explain almost 95% of all the cases I have investigated. All of them (except surface wear) are easily rectified. A gloss meter is a helpful tool for determining if there is a problem as well as qualifying the effectiveness of the solution.